If your new to the world of heat transfer vinyl, Siser is one of the most recognized manufacturers of HTV in the world and their flagship product, EasyWeed, is preferred by many crafters and apparel decorating professionals alike. Why you ask? Because it does what its name suggests, it's really easy to cut, weed away the waste, and apply. The sticky carrier makes also makes it the ideal choice for small details and lettering.

Siser EasyWeed has also been certified to use on children's clothing and is CPSIA certified. It's made out of polyurethane instead of pvc plastic so it's more earth-friendly also.

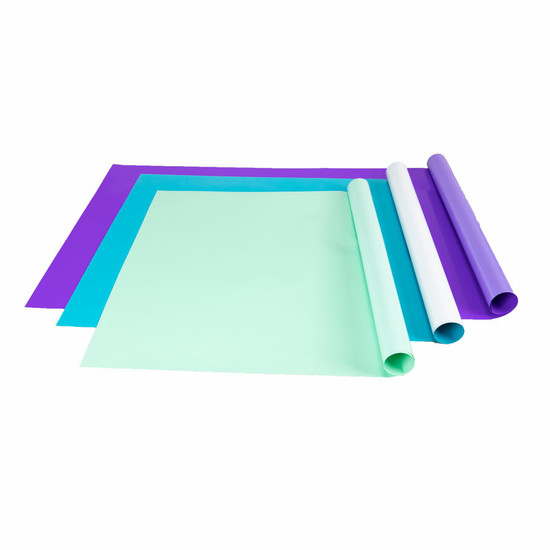

We offer 12" wide Siser EasyWeed HTV in several popular pre-rolled lengths including 5-yards, 10-yards, 25-yards and full 50-yard master rolls. EasyWeed 12" wide rolls work with small craft cutters and pro vinyl cutters alike and offer the convenience of ready-to-go lengths.

Siser EasyWeed 12" Wide Roll Specifications:

- Actual roll width is 11.8"

- Choose from four machine-rolled sizes including 5-yards (15 ft.), 10-yards (30 ft.), 25-yards (75 ft. ) and full 50-yard master rolls (150 ft.)

- Thickness: 3.5 mils (3.5/1000")

- Finish: semi-gloss except for the matte colors which are flat

- Sticky backing sheet (carrier)

- Limited stretchability

- Layerable

- Laser cutter compatible

- Applies to cotton, polyester, cotton/poly and cotton/poly/rayon blends

- Applies with a heat press or hand iron

- CPSIA certified

- All vinyl rolls that we offer may contain a random splice

Siser EasyWeed Color Choices:

The colors samples provided here may not be exact representations of the vinyl colors. Various factors such as monitor resolution, color settings and display type can all effect how the colors are viewed on the Internet.

Moisture Wicking Materials:

This type of fabric is heat sensitive and the regular temperature setting may leave a heat/bounding box that will not fade. Siser EasyWeed can be applied at a temperature as low as 280?F but the press time will need to be increased. When testing, increase the press time in 5 second increments until good adhesion is achieved. Testing with a spare garment is highly recommended.

Note: Because of the wide variety of fabrics and garment manufacturers that exist, we highly recommend that this product be fully tested prior to going into production.